Pattern detection of internal prestressing wire breaks on concrete surfaces

All over the world, infrastructure, and bridges in particular, are getting on in years. A wide variety of damage mechanisms and increasing loads have taken their toll. Individuality, sustainability and economic viability require careful consideration of their maintenance or necessary replacement in each individual case. Such decisions are based on recalculations and increasingly on structural health monitoring. The latter claims to always announce impending failure in good time; in reinforced concrete construction through the nowadays established criterion of "crack before failure", which is often not fulfilled in existing structures.

Imminent brittle failure, for example due to unnoticed tendon rupture, places special demands on this, which are only inadequately met by current methods such as acoustic emission or coda-wave interferometry. Monitoring must be global, i.e. it must monitor the entire bridge. At the same time, it must be robust and selective with respect to real environmental conditions, noise or a (temporary) failure of the measurement technology. The sensor network must be dense and sensitive in order to provide precise information about the condition.

The highest precision is provided by direct measurements of structural quantities, such as strains. However, the view inside is obstructed, and waiting for a visible crack formation is not an option. This is where the research project starts.

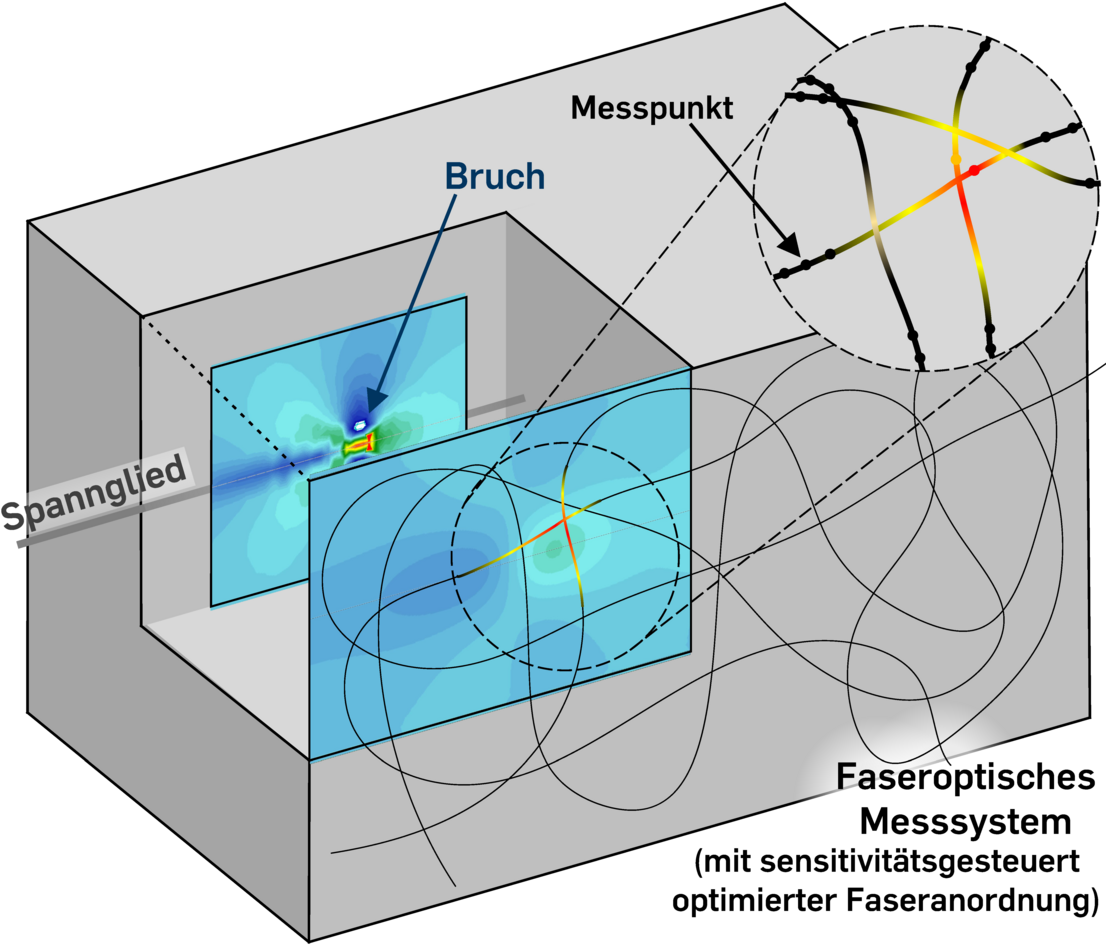

The aim is to detect even small internal damages by permanent two-dimensional strain measurements on the concrete surface - long before a crack becomes visible. As an "improved eye of structural inspection", the system detects discontinuous strain fields caused by wire rupture based on characteristic patterns at any damage location and with low intensity. Crossed fiber-optic sensors are used to record the strain patterns of the rupture and a re-anchoring quasi-continuously. Optimized measurement configurations in terms of frequency, fiber arrangement and distributions make the smallest strain changes usable and specify requirements for data storage and formats.

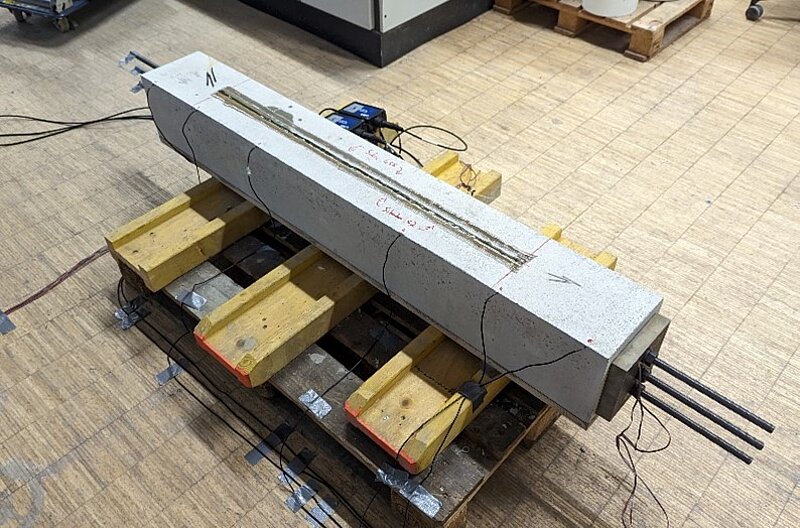

In consecutive experiments on small and large scales and corresponding stochastic finite element simulations, the rupture and the propagation of the strain fields induced by it are systematically analyzed.

Material- or damage-related uncertainties are included in Monte Carlo simulations and are evaluated with sensitivity analyses with regard to their effects on the measurement result. The core is an automated preparation and differentiation of the characteristic patterns from those of external disturbances, ambient influences or traffic with procedures of pattern recognition and discriminant analysis, which simultaneously allow the discriminatory power to be evaluated. The conceptual transfer to the demonstrator bridge shows and evaluates the feasibility on a large scale, taking into account practical construction conditions and constraints.