Measurement-based condition assessment of prestressed concrete bridges with low shear reinforcement ratios under fatigue loading for service life prediction on a digital twin

Older prestressed concrete bridges were designed for a combined load of shear force, torsion and bending basing on principal stresses and have only small amounts of steel reinforcement. Verifications according to current codes, reveal computational deficits, i.e., too little steel reinforcement in webs, bending tension zones or coupling joints. If visual inspections of such highly prestressed existing structures reveal visible damage, the structure is usually downgraded in bridge class, strengthened for temporarily limited use or even taken out of operation prematurely in order to prevent static or fatigue-induced failure.

However, state of the art is that structures resist static and cyclic loads for many years after the development of macrocracks with limited crack widths, until the serviceability and load-bearing capacity is finally lost. So far, these reserves usually remain unused, as on the one hand information for the continuous assessment of the time-variant structural condition and on the other hand suitable methods for predicting the remaining service life are missing.

The aim of the project is therefore to develop a deformation-based monitoring concept and physical prediction models based on it in order to be able to predict the remaining service life of existing prestressed concrete bridges more precisely using continuously obtained measurement data.

Measurement concept development

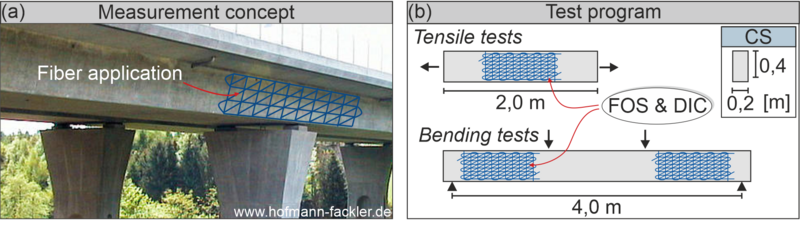

To determine the fatigue-relevant strains of the structure as well as the resulting micro- and macrocrack widths, critical areas of the structure are equipped with a fiber optic measuring network. The basic suitability of such systems has been confirmed in our own preparatory work [1]. So far, fiber optic measurement methods have mainly been used for one-dimensional strain measurements. However, the use of measuring networks installed on concrete surfaces for the high-resolution determination of strain fields has so far remained largely unexplored. Therefore, different fiber coatings, application methods, grid spacings and sampling rates are investigated in strain tests and flexural tests under static load, regarding their suitability for the determination of the concrete strain state. To evaluate the respective measurement quality, the strain results obtained by means of fiber optic sensors (FOS) are checked by measurements with Digital Image Correlation (DIC).

Evaluation methodology on the digital twin

The mesh-like installed measuring fiber initially provides one-dimensional strain raw data of the real twin. In order to transform the one-dimensional strains along the fiber path into a two-dimensional strain field, a transformation algorithm is developed. Spatial and temporal filtering of the strain raw data results in local strain information condensed to selected nodes. Using suitable approaches for strain interpolation between adjacent nodes (linear, quadratic, etc.), smoothed strain and relative deformation fields can be visualized. As long as the concrete is uncracked, in the next step the main strains can be determined by a principal axis transformation from the strains measured in three independent directions. In addition, based on our own preliminary work [1], a routine is being developed that automatically detects and localizes cracks when the structure transitions to State II. All aggregated (principal) strain and crack width information is integrated into a 3D geometry model of the structure. This digital twin is the central element of data organization, where all time-invariant and time-variant structure information is kept, monitored, and provided for the prediction models.

Data aggregation and implementation in a lifetime prediction model

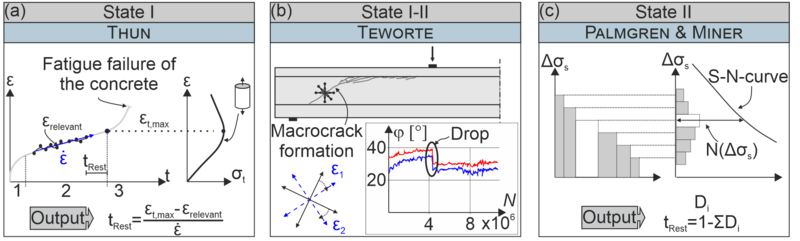

In a prediction model to be developed, (a) the behavior before macrocrack formation (State I), (b) the transition from State I to State II and (c) the fatigue of the shear force reinforcement after the occurrence of the macrocrack (State II) are characterized and predicted. The fatigue criterion proposed by Thun [2] and confirmed in our own preliminary work [3][4] is used to predict the remaining service life until the onset of unstable microcracking. The principal strain data provided by the digital twin are used, assuming a linear strain increase, to calculate the remaining service life before the onset of macrocracking. Strains from the premature loading history of the structure are considered. A change in the principal compressive stress angle by about 10-12°, observed in our own preliminary work [5], serves as an indicator for the localization of a crack band to a critical macro shear crack. Once the critical macro crack has fully formed, fatigue of the shear force reinforcement begins. The Palmgren/Miner linear damage accumulation hypothesis described in [6] is used to predict the remaining service life of the shear reinforcement in State II. For each shear reinforcement crossing a shear crack, the remaining load cycles can be estimated by comparison with a material-specific S N curve. If the successive fatigue failure is tracked metrologically and computationally, the comparison with the residual load-bearing capacity leads to the prediction of the global remaining service life.

Calibration and validation by component tests

By means of large-scale beam tests, the developed measurement concept is validated, as well as the evaluation methodology in the digital twin, and the accuracy of the models for predicting damage and remaining service life. Geometry, reinforcement ratio, prestressing ratio and concrete strength of the test beams are based on real prestressed concrete bridge girders with hollow box section, which are reduced for the experimental investigations to an I-cross-section with web, top and bottom chord. To verify the fiber-optic strain measurement, the strain development in all partial tests is monitored by means of Digital Image Correlation and the shear reinforcement is equipped with strain gauges.